Duct Work

Most air conditioning and heating systems require some form of duct work to channel or direct the air to places where the conditioned air is needed. There are

many types of ductwork available and often times the ductwork can make a big

difference in your utility bills. For that reason, it is important that the ductwork is

designed and installed correctly. A poor installation job will result in poor

performance, bad air flow, leaky duct systems, and higher than usual utility bills.

Another important factor in the installation process is to make sure the duct work is

sized properly. Over sizing systems cost more and does not maintain the desired air

flow and undersized duct work causes the system to strain mechanically and can be

noisy.

Duct

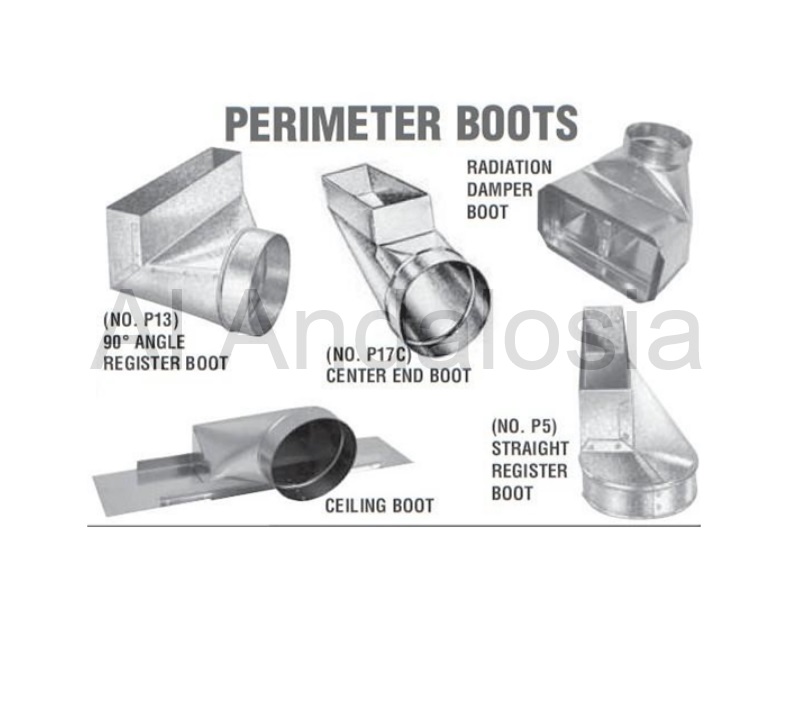

A duct system is a network of round or rectangular tubes—generally constructed of sheet metal, fiberglass board, or a flexible plasticand- wire composite—located within the walls, floors, and ceilings. Usually, you can see only the outlet, which is a register covered with grillwork.

The purpose of a duct system is to transmit air from the central air source to the air diffusers located in the building control zones. Figure below shows a central heating furnace connected to supply and return air ductwork. The furnace is connected to the air plenum at the starting point. Furnace fan/s draw air in through grilles called returns and force air through the plenum and into the conditioned space through supply registers.

Description

Straight duct, stiffened with transverse trapezoid corrugations, which reduces the risk of noise generation. Larger dimensions have stiffening profiles and/or internal rods. Installation height of these profiles is 23 mm.

Ducts are normally supplied with a strong joining, but can also be supplied as a flexible piece, where the joining profile on one end is not fixed. Also available with an end cover fixed by joining profiles.

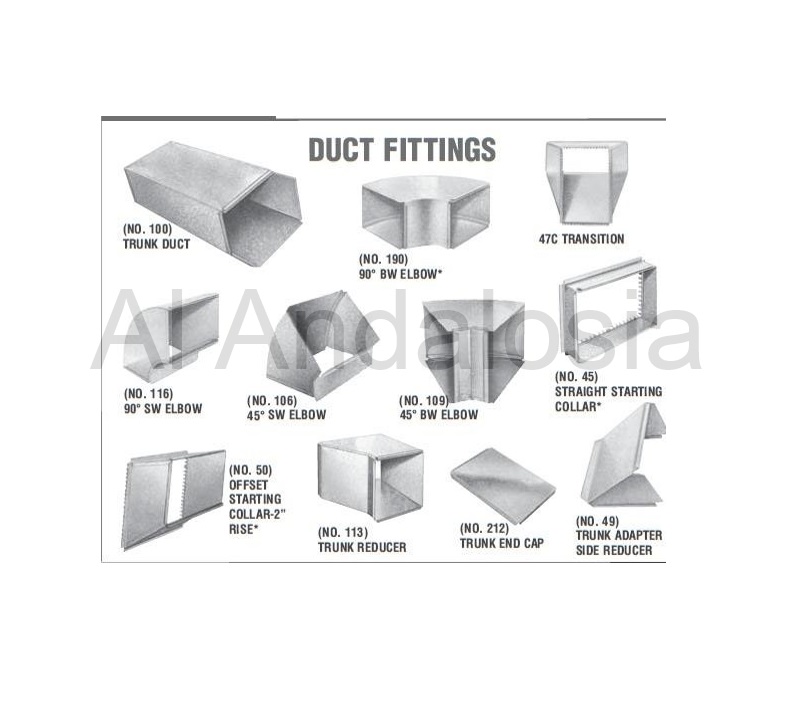

Bend

Elbows – A variety of elbows are available for rectangular duct system. Elbow types range from mitred to long radius. Long radius elbows are most efficient. An elbow with a centerline radius (r/D or r/W) of 1.5 is very efficient and should be used in cases where duct air velocity is 2,500 fpm or higher. A standard radius elbow (r/D of 1.0) is more economical and only slightly less efficient; it is generally preferred. Short radius elbows are those with an inside throat radius less than the turning width of the duct, but in no case may this throat radius be less than 3 inches. To improve the efficiency of short radius elbows splitter vanes should be provided as follows:

- A single splitter vane should be provided in short radius elbows with a turning width of 12 inches or less.

- Two splitter vanes should be provided in short radius elbows with a turning width of 12 to 24 inches.

- Three splitter vanes should be provided in short radius elbows with a turning width of over 24 inches.

Description

Bend with rounded outer corner, stiffened with trapezoid corrugations. Other leg lengths and angles can also be ordered. Standard design l1 = l2 = 125 mm.

S-bend

Used for deflections of the duct system, for example where ducts cross. Has a joining profile type RJFP at both ends, and is stiffened by trapezoid corrugations.

A special relationship is needed between the a-dimension, fall f and length l for the LBSR to retain its cross-sectional area and not restrict the air flow. For this reason, standard lengths and standard drops have been prepared.

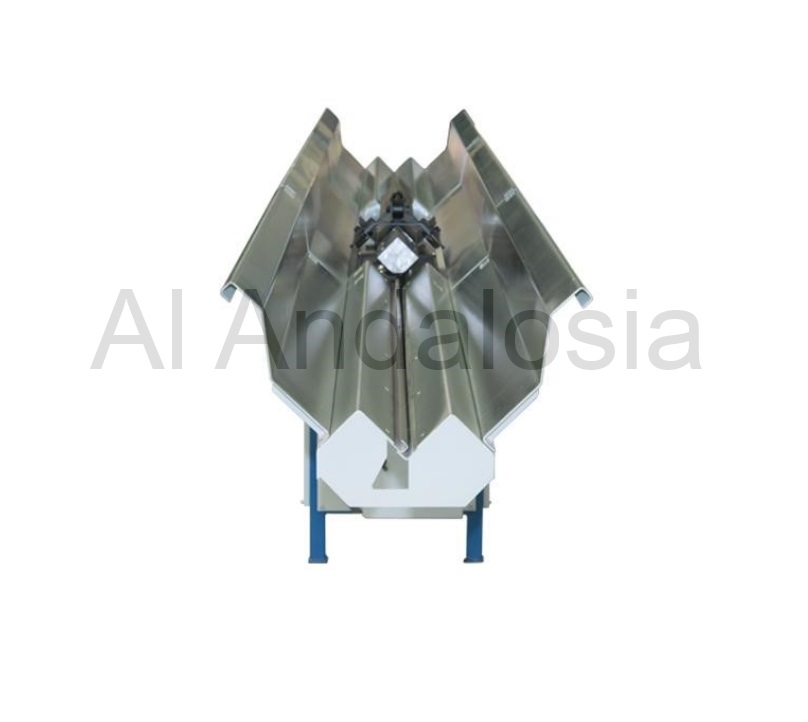

Taper

The taper is used as transition between different duct dimensions. The larger dimensions are available with offsets as in the coded sketches.

Dimension changes have a joining profile type RJFP at both ends, and are stiffened by trapezoid corrugations.

Rect-to-round transition

Rect-to-round transition are used between rectangular and circular ducts. The rectangular connection has joining profiles type RJFP and the circular connection has Safe seal. The rectangular connection is available with offsets as in the coded sketches.

Collar

The collar is used for connection to rectangular duct. The smaller joint end is provided with joining profiles type RJFP. The larger one has an edge, for fixing with blind rivets or self-tapping screws, but can also be given a folding tab to facilitate assembly.

Collar on circular duct

The collar is used for connection to circular duct. The rectangular end is provided with joining profiles type RJFP. The rounded end has an edge, for fixing with blind rivets or self tapping screws. Other lengths can also be supplied.

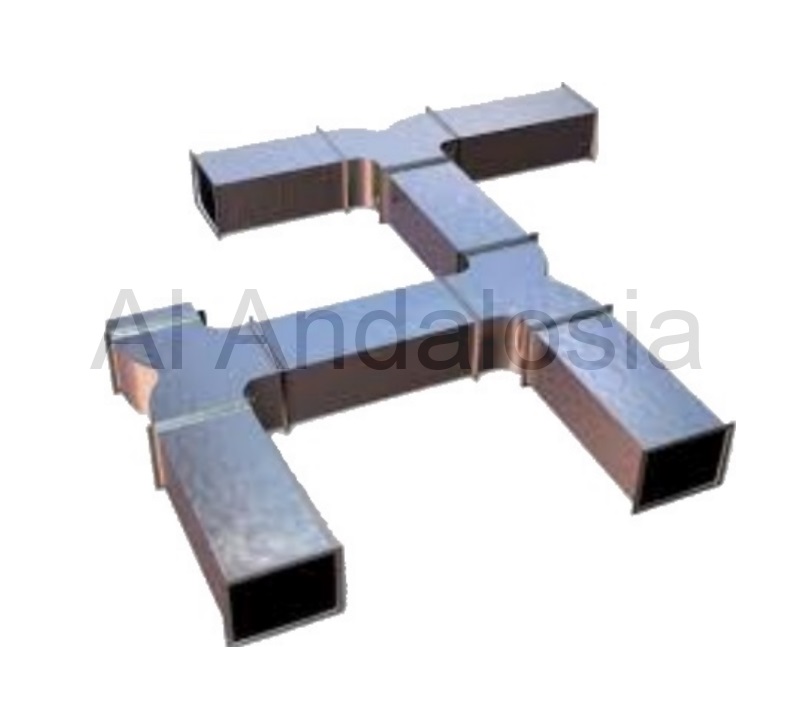

T-piece

A T-piece which is provided with joining profiles type RJFP and is stiffened with trapezoid corrugations.

Standard design l1 = l2 = l3 = 125 mm.

Other leg lengths can also be supplied.